welcome to omiocnc.com

Shopping Policy

- Shipping by DHL/FEDEX/TNT, more>

- We accept PayPal, you can use credit card through PayPal.

- Estimated Shipping Time: 10 - 15days

- Buyer Protection: Full Refund if you don't receive your order.

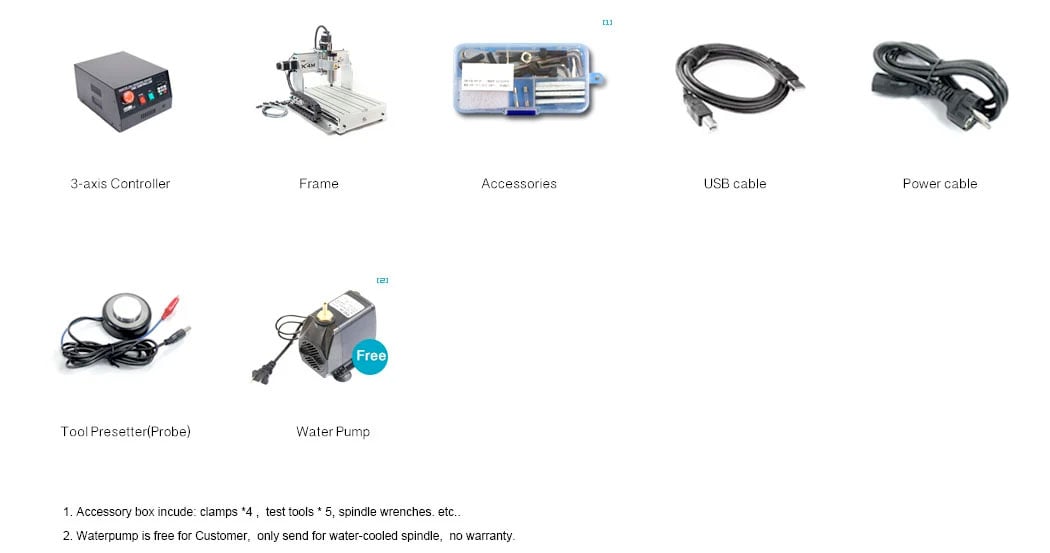

- Free Water pump (only for machine with water-cooling spindle).

Customer Services

Payment and Shipping

Company Policies

Business Cooperation