X6-2200EPL

◎ High-performance OMIO-EPL-4F Offline Control System, it can be directly run G-code and not needs to be connected to computer, so it will not be disturbed from computer, thus ensuring the stability of long working hours.

◎ Supports multiple coordinate systems and save breakpoints. if you have to leave when machine is engraving, you just need to pause the engraving, and you can continue to engraving work on next day. when a sudden power failure, the coordinates could be automatically saved , and you can continue to engraving work when the power is restored.

◎ XYZ-axis all equiped Linear Guide Rails, that makes the 2.2kw spindle plays perfect cutting performance. the maximum diameter of cutter is 13mm (required to purchase appropriate collet).

Uniaxial output pulse up to 500KHz, adjustable pulse width, supports high versatility FANUC compatible G-code instruction set.

X6-2200EPL no longer needs to work with computer, it was greatly enhanced the stability and reliability. Technicians can design and processing G-code in the office, then just send the G-code file to operatives.

OMIO-EPL-4F Control System supports G-commands :

G0, G1, G2, G3, G17, G18, G19, G20, G21, G54, G55, G56, G57, G58, G59, G60, G81, G82, G83, G90, G91, G98 , G99.

Note: This machine does not come with any CAM software, please choose CAM software suitable for your company according to the advice of your engineer.

◆ The frequently used CAM software in engraving machine areas: ArtCAM, AlphaCAM, Aspire, Artcut, Cut2D / 3D, CopperCAM, DeskProto, Type3, UcanCAM, these software can be directly export G-code file. we recommend using these software, the details please consult the software provider.

◆ Other industrial CAM software (such as Mastercam, PowerMill, HyperMill, Pro/E, UG, Lemoine RTM, etc.) may be required post-processing program, please consult the software provider.

◆ SolidWorks, AutoCAD, CorelDRAW software can not directly generate G-code files , but they can exporte '.stl', '.eps', '.dxf' file, these format files can be imported to ArtCAM, Cut2D/3D, DeskProto, Artcut software, then export G-code files.

We recommend it to you, X6-2200EPL is the best choose in a similar price range.

X6-2200EPL machinable size is 565 * 770mm , mainly used for batch processing operations with plastic, copper, aluminum and other materials.

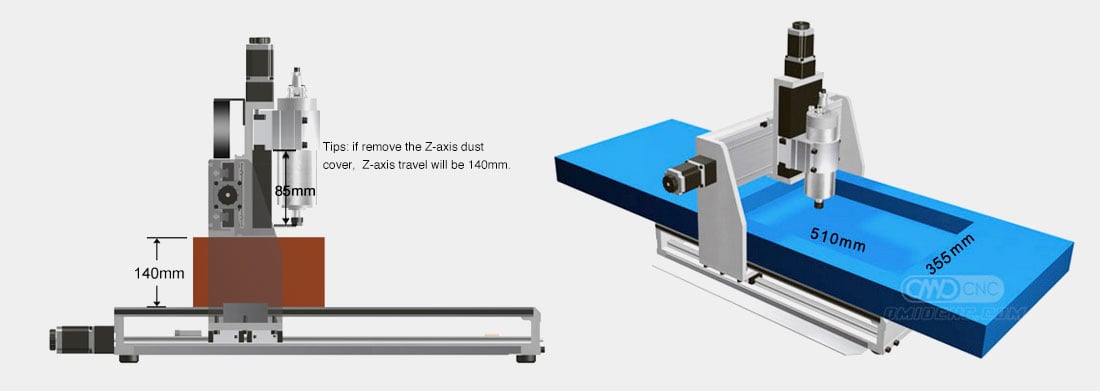

| Max. working stroke: | (X)355×(Y)510×(Z)85mm (Tips: if remove the Z-axis dust cover, Z-axis travel will be 140mm.) |

| Acceptable material thickness: | ≤140mm |

| Frame Material: | 6061-T5 extruded aluminum alloy |

| Rail type: | HG20 Linear Guideway |

| Screw Type: | Ball screw, diameter 16mm,screw thread pitch 5mm |

| Positioning accuracy: | 0.05mm |

| Spindle Motor: | Powerful brushless frequency spindle,2200W |

| Revolution Speed: | 6000~24000rpm/min |

| Collet type: | ER20(standard equipped with 6mm collet, If need other size collet, please see here.) |

| X/Y/Z Stepper Motor: | Stepper Motor 57BYGH76-3.0A |

| X/Y/Z/A Stepper Drives: | High performance Digital Stepper Drives |

| Feed rate: | 100~4000mm/min |

| Control System: | OMIO-EPL-4F CNC system |

| Acceptable Command code: : | G-code (file type: /.nc/.ncc/.tap/.txt) |

| Power: | 100V-120V or 220V-240V |

| Environment: | Temp: 5°~40° C; Humidity: 35 to 80% |

| Equipment dimensions: | L880 × W665 × H655mm |

| Machine weight: | 68kg |

| Package dimension: | 2 boxes (box1: 640x450x550mm, box2: 860x630x220mm) |

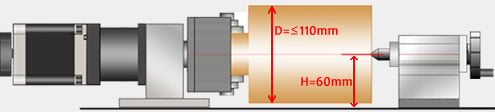

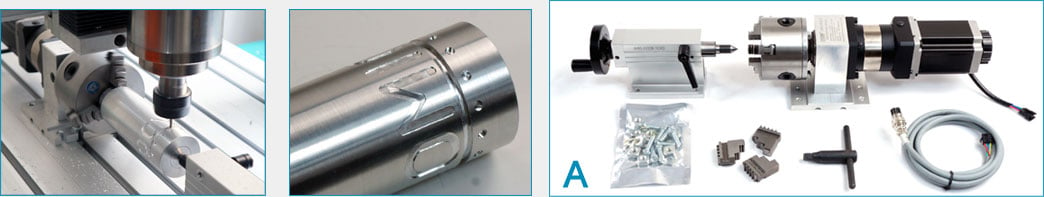

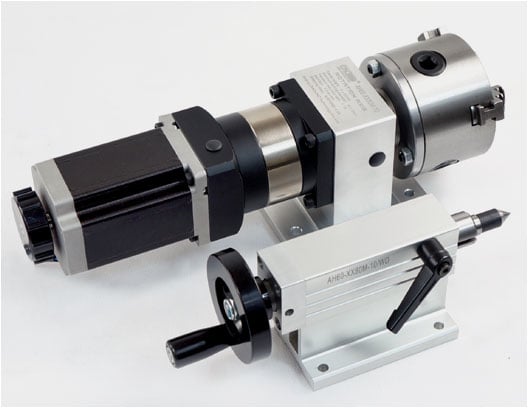

· 80mm 3 jaw chuck

· Center height: H=60mm

· Max swing diameter: ≤110mm

· Diameter of through hole: ≤16mm

· Reduction ratio: 1:10

· Deceleration method: Planetary reducer

· Maximum RPM: 100

· Processing materials: wood,plastic,copper and aluminum

· Weight: 7.0kg

See more >>